Hardware Development Lifecycle

Your Hardware Development Partner. Rapidise offers a structured product development lifecycle tailored to hardware projects, guiding you from initial concept to market launch. Our unwavering support ensures a successful journey at every stage.

Phase 1

SoW, PRD & Architecture

Scope of Work Finalization & A BoM Finalization

Qualcomm

Synaptics

NXP Semiconductor

Nordic Semiconductor

Quectel

Macronix

Micron

Product Requirement Document & Architecture Document

Winbond Electronics

KIOXIA America Inc.

Analog Devices/Maxim Integrated

ST Microelectronics

OSRAM

Panasonic

Texas Instruments

TDK Corporation

Microchip Technology

Renesas

TE Connectivity

AMP Connectors

Molex

Hirose Electric Co Ltd

Samtec

Phase 2

Schematic Design

Power Budget Analysis & GPIO Pin Mapping

High Speed Digital Board Designs

Low Speed Digital Board Designs

RF and Wireless Design Solutions

MCU Designs

Schematic Library Creation & Schematic Drafting

Power-optimized & Battery Operated Designs

Development Platforms

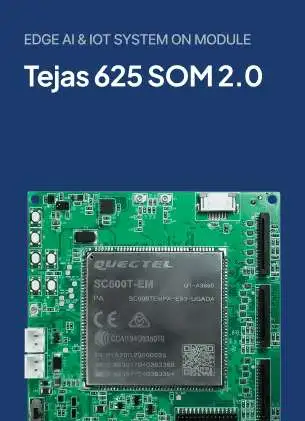

System-on-Modules (SoM)

Embedded Processor Based Designs

BoM Creation & Finalization

Analog and Audio Circuit Designs

Design Estimations/ BOM Optimization

ADCs and DACs

Allegro, OrCAD, Altium, Ki-CAD

Phase 3

Layout Design

Footprint Creation & Get the PCB Stack Up

Library Management

Small Footprints

PCB Stack Up Design

Board Size and Net Count

Signal Integrity

Layout Design & Gerber Release

Power Integrity

Thermal Analysis

Power Distribution

EMI and EMC

Design Rules and Constraints

PCB Fabrication & SMT Assembly

Component Clearance and Mechanical Constraints

Design for Manufacturing (DFM) Analysis

Design for Assembly (DFA) Analysis

Design for Testing (DFT) Analysis

Allegro, OrCAD, Altium, Ki-CAD

Phase 4

Bring up & Product Delivery

Test Cases Preparation, Finalization & PCBA Bring Up EDVT Report

MIPI CSI & DSI, LVDS

Ethernet SGMII & RGMII

Ethernet PHY USB

PCI Express, HDMI, CAN, SATA

GPS, GSM, WiFi, Bluetooth, LTE, NFC

Touch Screen

QA/QC Testing & Final Delivery of Product

AMIC, DMIC, SoundWire, SLIMbus Digital Audio

LDDDR3ILPDDR4ILPDDR4X /LPDDR5

DDR2IDDR3IDDR4 SDRAM

SDIO, SDC, eMMC/UFS, eMCP

Sensors I2C, SPI, UART

RFQ to FDR Rapidise Project Delivery Cycle

Requirements finalization

Product Requirement Specification Phase

Finalizing requirements in an embedded project is an important step in ensuring the successful development and deployment of the system. Here are some key steps and considerations for finalizing requirements in an embedded project

Requirement Identification

Requirement Analysis

Prioritization and Classification

Requirement Traceability

Requirement Validation

Requirement Documentation

Change Management

Architecture Phase

Product Specification

Hardware Architecture

Hardware Design Limitation

Overall BOM Cost

Major Component Selection

Technical Stack

Assumption

Gray Areas

Acceptance Criteria

Risk Factors And Mitigation Plan

Block diagram

Pin Mapping

Power Budgeting

FMEA (Failure Modes and Effects Analysis)

Major Component Selection

When selecting major components for an embedded project, there are several criteria to consider.The specific criteria may vary depending on the nature of the project,but here are some common factors to evaluate:

Submitted by Client

Functional Requirements

Performance

Quality and Reliability

Availability and Longevity

Cost

Compatibility and Interoperability

Development and Support

Scalability and Flexibility

Power Efficiency

Safety and Compliance

By carefully evaluating these criteria and conducting thorough research, you can select major components that align with the project’s requirements, budget, and long-term objectives.

Schematic Design

When creating a schematic design for an embedded project, there are several criteria to consider. The schematic design is a crucial step in defining the electrical and functional aspects of the system. Here are some key criteria to keep in mind:

When selecting major components for an embedded project, there are several criteria to consider. The specific criteria may vary depending on the nature of the project, but here are some common factors to evaluate:

System Requirements

Component Selection

Signal Integrity

Power Distribution

EMI/EMC Considerations

Documentation and Clarity

Revision Control

Collaboration and Feedback

By considering these criteria, you can create a well-designed schematic that effectively represents the electrical aspects of your embedded project and serves as a solid foundation for further development and implementation.

BOM Creation

Component Information

Quantity and Units

Supplier and Pricing Information

Manufacturer and Distributor Support

Alternatives and Second Sources

Lifecycle and Obsolescence Management

BOM Version Control

BOM Creation

Component Datasheets

IPC Standards

Component Geometry

Pad Design

Solder Mask and Paste Mask

Thermal Considerations

Manufacturing Constraints

Silkscreen and Reference Designators

Verification and Validation

Documentation

Keep-out Zones

Component Placement

Signal Integrity

Thermal Management

Power Distribution

Iterative Optimization

Manufacturing and Assembly

Design for Testing (DFT)

Documentation and Clarity

Design Rules and Constraints

Electromagnetic Compatibility

Component Clearance and Mechanical Constraints

Electro mechanical verification

Dimensional Compatibility

Mechanical Stress and Strain

Electrical Connection

Electrical Grounding

EMI/EMC Compliance

Mechanical and Electrical Safety

Functional Integration

Thermal Management

Environmental Durability

Documentation and Standards Compliance

PCB Layout

Component Placement

Signal Integrity

Power and Ground Planes Incorporate

Routing and Trace Considerations

Thermal Management

Design for Manufacturing (DFM)

Design for Testing (DFT)

EMI/EMC Considerations

Component and Footprint Selection

Documentation and Verification

Revision Control

Board Bring up

Power Supply

Component Placement

Solder Joints

Signal Integrity

Clock and Timing

Power Integrity

Functional Testing

Thermal Management

Compliance and Standards

Hardware Firmware Integration (dump code)

The criteria for hardware-firmware integration, specifically when it comes to integrating firmware (also known as “dump code”) with hardware, typically involve the following considerations

Firmware Compatibility

Hardware Initialization

Communication Interfaces

Register Configuration

Peripheral Integration

Memory Management

Error Handling and Fault Tolerance

Real-Time Constraints

Integration Testing

QA/QC Testing

Test Planning

Functional Testing

Performance Testing

Usability Testing

Compatibility Testing

Security Testing

Regression Testing

Stress and Load Testing

Compliance Testing

Documentation Review

Bug Tracking and Reporting

Continuous Improvement

Final Testing

System Integration Testing

End-to-End Testing

User Acceptance Testing (UAT)

Performance and Scalability Testing

Security and Penetration Testing

Compatibility Testing

Accessibility Testing

Regression Testing

Reliability and Stability Testing

Disaster Recovery and Backup Testing

Compliance and Certification Testing

Documentation and Release Readiness

User Feedback Incorporation

Shipment & Release

Quality Assurance

Regulatory Compliance

Manufacturing Readiness

Inventory Management

Documentation and Manuals

Order Fulfillment

Logistics and Shipping

Export and Import Compliance

Component and Footprint Selection

Documentation and Verification

Revision Control

PCB Layout

Component Placement

Signal Integrity

Power and Ground Planes Incorporate

Routing and Trace Considerations

Thermal Management

Design for Manufacturing (DFM)

Design for Testing (DFT)

EMI/EMC Considerations

Component and Footprint Selection

Documentation and Verification

Revision Control

Industries We Serve

Rapidise caters for many industries and offers specialized and unique industrial solutions within sectors. We appreciate that each industry has its strengths and weaknesses, and we tap into it to facilitate your business objectives.

Our Technology Marketplace

Accelerate your Product Development with a Ready made HW, SW, or AI Solution

Browse the Rapidise tMarket for a vast selection of matured accelerator solutions ready to implement into your product now which decrease down-stream costs and accelerate your time-to market. SOMs & SOCs, SDKs, AI Models & Libraries, and more…