Introduction

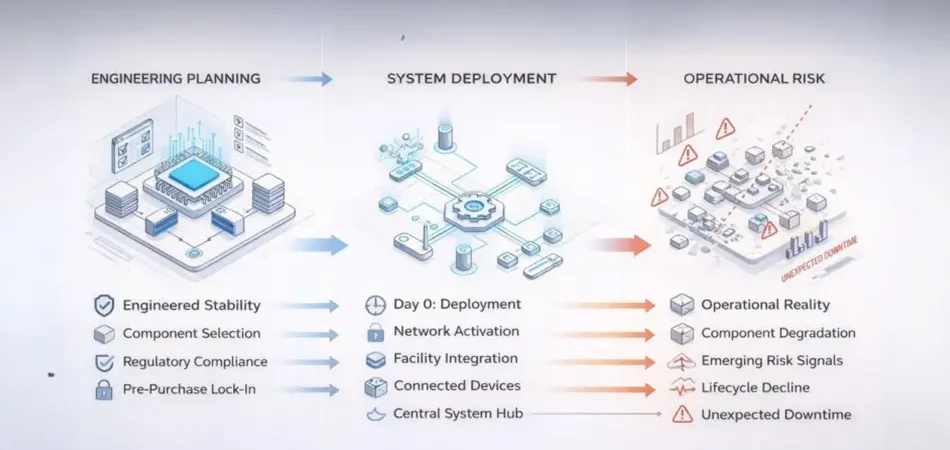

BLE Beacon deployments are almost never conceived as short-term initiatives. In sectors such as asset tracking, industrial safety, smart manufacturing, and IoT-enabled security, these devices are installed with the expectation that they will operate reliably for many years with minimal intervention. Despite this reality, most BLE Beacon programs continue to prioritize speed to launch over long-term sustainability. Hardware decisions are often finalized to meet immediate certification and cost targets, while lifecycle resilience is treated as a secondary concern.

This imbalance rarely becomes visible during pilots or early rollouts. Instead, it emerges gradually as deployments mature, typically in the second or third year, when component availability, supply chain variability, and certification constraints begin to influence system behavior.

This imbalance rarely becomes visible during pilots or early rollouts. Instead, it emerges gradually as deployments mature, typically in the second or third year, when component availability, supply chain variability, and certification constraints begin to influence system behavior.

The Mismatch Between Deployment Duration and Component Lifecycles

A BLE Beacon – whether used as a Bluetooth tracking device, a rugged industrial beacon, or an IP67-rated asset tag – is commonly expected to function continuously for three to five years or more. The operational assumption is stability, which means consistent RF performance, predictable battery life, and uniform behavior across the deployed fleet.

Internally, however, each beacon relies on a collection of electronic components that follow their own independent lifecycles. Microcontrollers, radios, power management ICs, and sensors are governed by semiconductor vendor roadmaps and market dynamics that often change far more quickly than the deployment itself. When these realities are not considered during hardware design and development, a structural mismatch is introduced – one that cannot be resolved later through firmware updates or operational workarounds.

Internally, however, each beacon relies on a collection of electronic components that follow their own independent lifecycles. Microcontrollers, radios, power management ICs, and sensors are governed by semiconductor vendor roadmaps and market dynamics that often change far more quickly than the deployment itself. When these realities are not considered during hardware design and development, a structural mismatch is introduced – one that cannot be resolved later through firmware updates or operational workarounds.

How Component Obsolescence Disrupts Long-Term Deployments

When a critical component becomes unavailable or reaches end-of-life, the impact extends well beyond replacing a single part. Even minor substitutions can alter power consumption profiles, RF characteristics, and thermal behavior. These changes frequently require firmware updates, validation cycles, and extensive regression testing to ensure the system continues to operate as intended.

In regulated or geographically distributed deployments, the consequences are even more significant. Hardware changes may trigger partial or full re-certification, increasing both cost and time to resolution. What was initially deployed as a standardized BLE Beacon platform can gradually fragment into multiple hardware revisions, each with slightly different performance characteristics. At scale, organizations are forced to either support parallel hardware versions or redeploy devices earlier than planned, both of which undermine operational efficiency and return on investment.

In regulated or geographically distributed deployments, the consequences are even more significant. Hardware changes may trigger partial or full re-certification, increasing both cost and time to resolution. What was initially deployed as a standardized BLE Beacon platform can gradually fragment into multiple hardware revisions, each with slightly different performance characteristics. At scale, organizations are forced to either support parallel hardware versions or redeploy devices earlier than planned, both of which undermine operational efficiency and return on investment.

Supply Chain Volatility Becomes a System-Level Risk

Supply chain instability is often addressed as a procurement issue, but in long-lived BLE Beacon deployments it quickly becomes an engineering concern. Over time, reactive substitutions made to address shortages or allocation constraints can accumulate across production batches. While each change may appear minor in isolation, the combined effect can introduce inconsistencies that surface in the field.

These inconsistencies manifest as unpredictable edge cases, uneven performance across deployment phases, and increased support complexity during system expansion. In environments such as real-time asset tracking, industry 4.0 implementations, or smart production systems, predictability and uniform behavior are essential. Hardware platforms expected to remain stable for years cannot absorb uncontrolled variation without compromising reliability and scalability.

These inconsistencies manifest as unpredictable edge cases, uneven performance across deployment phases, and increased support complexity during system expansion. In environments such as real-time asset tracking, industry 4.0 implementations, or smart production systems, predictability and uniform behavior are essential. Hardware platforms expected to remain stable for years cannot absorb uncontrolled variation without compromising reliability and scalability.

Certification Constraints Reduce Flexibility Over Time

BLE Beacon hardware is typically bound by RF, regional, and safety certifications that lock specific component configurations into approved designs. Once certification is complete, the ability to change components becomes significantly restricted. Late-stage modifications are not simply technical adjustments; they carry regulatory and compliance implications that can be costly and time-consuming to address.

As deployments scale, the practicality of re-certifying hardware diminishes. Design decisions made during new product introduction and early engineering phases therefore persist throughout the product’s lifecycle. Teams that underestimate this constraint often find themselves constrained by assumptions made years earlier, long after deployment requirements have evolved.

As deployments scale, the practicality of re-certifying hardware diminishes. Design decisions made during new product introduction and early engineering phases therefore persist throughout the product’s lifecycle. Teams that underestimate this constraint often find themselves constrained by assumptions made years earlier, long after deployment requirements have evolved.

Why Is ODM Ownership Central to Lifecycle Stability?

Effective lifecycle planning requires clear accountability, and this is where strong ODM ownership becomes critical. An experienced ODM approaches BLE Beacon development as a long-term platform initiative rather than a one-time product release. Change is not avoided, but it is managed deliberately through disciplined production and manufacturing engineering.

By aligning component selection with long-term availability roadmaps, planning second-source options early, and maintaining strict control over bill-of-material changes, ODMs ensure that hardware evolution does not disrupt deployed systems. Firmware continuity across hardware revisions is preserved through coordinated embedded hardware and embedded software development, allowing platforms to evolve without fragmenting the installed base.

By aligning component selection with long-term availability roadmaps, planning second-source options early, and maintaining strict control over bill-of-material changes, ODMs ensure that hardware evolution does not disrupt deployed systems. Firmware continuity across hardware revisions is preserved through coordinated embedded hardware and embedded software development, allowing platforms to evolve without fragmenting the installed base.

Lifecycle Planning as a Foundation for Customer Confidence

Lifecycle planning is often framed as an internal engineering best practice, but its impact is most visible to customers. Well-managed hardware lifecycles enable predictable expansion, consistent performance across production years, and lower total cost of ownership. For system integrators and end customers, this translates into fewer surprises and greater confidence that the deployed solution will remain viable over time.

Rather than forcing unplanned redesigns or early redeployments, lifecycle-driven platforms support growth and adaptation within the original business case. Trust is built not through promises, but through stability delivered over years of operation.

Rather than forcing unplanned redesigns or early redeployments, lifecycle-driven platforms support growth and adaptation within the original business case. Trust is built not through promises, but through stability delivered over years of operation.

Engineering Longevity from the Start

BLE Beacon deployments rarely fail at launch. More often, they degrade incrementally through unmanaged component changes, overlooked dependencies, and assumptions that no longer hold at scale. Teams that avoid these outcomes make lifecycle decisions early, when flexibility is still high and change is relatively inexpensive.

In long-lived systems, longevity is not an afterthought. It is the result of deliberate engineering choices made during hardware product development, new product introduction, and manufacturing planning.

In long-lived systems, longevity is not an afterthought. It is the result of deliberate engineering choices made during hardware product development, new product introduction, and manufacturing planning.

Why Rapidise Is the Right Partner for BLE Beacon Platforms

Rapidise approaches BLE Beacon development with a full-lifecycle engineering and manufacturing initiative. By combining embedded hardware design services, embedded software development, and electronics manufacturing services, Rapidise aligns design, certification, and production decisions with real-world deployment timelines.

From new product introduction and hardware lifecycle planning to mass manufacturing and ongoing BOM governance, Rapidise enables BLE Beacon platforms that remain stable, scalable, and cost-effective over time. This integrated approach ensures that deployments can grow and evolve without forcing premature redesigns or redeployments.

When BLE Beacon deployments are expected to last for years, the engineering behind them must be built with the same long-term perspective.

From new product introduction and hardware lifecycle planning to mass manufacturing and ongoing BOM governance, Rapidise enables BLE Beacon platforms that remain stable, scalable, and cost-effective over time. This integrated approach ensures that deployments can grow and evolve without forcing premature redesigns or redeployments.

When BLE Beacon deployments are expected to last for years, the engineering behind them must be built with the same long-term perspective.

Ensure Stability in Your BLE Beacon Lifecycle

To Implement Strategic lifecycle planning for seamless RTLS solutions